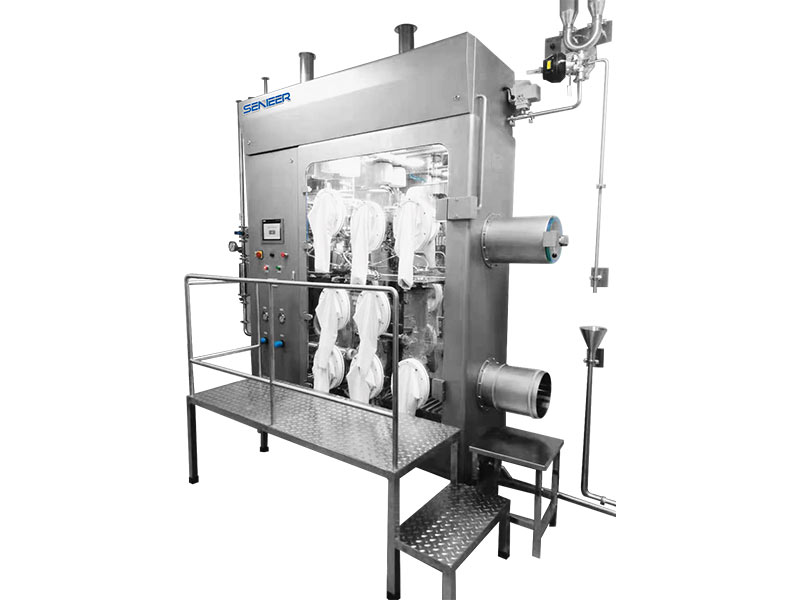

OEB 4/5 High Containment Fluid Bed Granulator Features:

- Designed for highly active and toxic OEB 4 and OEB 5 drugs

- Highly precise, dense, and uniform granules

- A unique air inlet process and treatment system with various shapes to meet customer needs.

- Multiple chamber system with unique filters and air-filled sealings

- Efficient Binder spray system with one or multiple unique nozzles.

- Dust-free processing and production; ensure no cross-contamination

- WIP online cleaning system makes cleaning easy

- Our Fluid bed granulator is compliant with cGMP and FDA norms

- Siemens smart touch screen and fully automatic PLC control system

- We can also provide an anti-1 Obar detonation design at the customers’ demand.

OEB 4/5 High Containment Fluid Bed Granulator Features:

Senieer is a prime pharmaceutical brand. We offer you a wide range of fluid bed dryer granulator machines. Our machines are designed to process OEB 5 compounds. The fluid bed granulation process includes suspending particles in an air stream. After suspending, the machine sprays a binder liquid on the particles in the fluid bed from top to bottom.

The use of OEB 4 and OEB 5 compounds has greatly increased in the past few years. Senieer is aware of the adverse effects of these active and toxic compounds. Hence, we have designed our fluid bed granulators with special and modified features to provide OEB 5 containment level.

Senieer’s fluidized bed granulator integrates top spray fluid bed granulation and drying in a single unit. In the fluid bed granulation process, our machine first reduces the moisture content of the input material. Then, a spray gun system is used to spray atomized binder onto the suspended granulate.

Our fluidized bed spray granulation is the latest technology in the pharmaceutical industry. Our machines are available in standard as well as custom designs. We provide unique air inlet systems with different configurations and anti-1 Obar detonation designs based on customers’ demands.

Senieer’s fluid bed granulator is made with the latest technology. Our machines are fully automatic and incorporate Siemens smart touch screen system. Also, we have introduced an automated PLC control system to operate easily. We have highly qualified experts who strive to make our machines cost and environment friendly.

Senieer’s OEB 5 Fluid Bed granulator is made up of an air handling unit, filter system, and a unique spray system. Our machines also have a built-in WIP online washing system and a stainless steel structure with many safety features.

A constant supply of purified air and precisely controlled temperature and humidity are important conditions that ensure high product quality. Senieer’s high containment fluid bed granulator incorporates an efficient and optimized air handling unit to process OEB 5 compounds.

The inlet air is purified by multiple filters and taken in by an induced draft fan to the lower parts of the fluid bed granulator. Hot, high-pressure, and dry air is filled in the machine through a vacuum. The moist solid granules rise from the bottom and suspend in a current of air while remaining in the fluidized state. Filters also prevent the air from flowing back to the heating system from the granulation fluid bed chamber.

The water and solvents are evaporated from the granulate due to heat transfer and low humidity inlet air. Direct contact between hot air and wet granules allows effective heat transfer and perfect material drying. These features effectively reduce the moisture content of the material in the fluid bed granulation process.

The outlet air is filtered inside the machine to remove remnants of OEB 5 compounds. To meet the special emission control regulations of OEB 5 drugs, we provide various secondary filters and a dust separation plant. A silencer or sound insulation feature effectively reduces the exhaust noise.

Senieer’s fluid bed granulator has air-tight seals and a strong stainless-steel body. No cross-contamination of OEB 5 compounds occurs, rendering a safe working environment for operators and workers.

The top spray fluid bed granulation allows to carry out the process inside a fluid bed. The movement of the powder in a fluidized state is combined with the spraying of a binder solution. The suspended fluidized material is sprayed with an atomized binder solution.

The binder solution makes the small powdery particles wet and sticky. The sticky particles collide with one another in a fluid bed and bind to each other. This process is repeated continuously to form perfect dry granules. This combination allows for an increase in the particle size generating a dense granulate inside the fluid bed spray granulator.

Senieer has a wide range of models of high containment fluid bed granulators, possessing unique features. These models are available in standard as well as custom designs. For people in search of quality fluid bed granulation, Senieer is the best equipment partner.

With our years of industry experience, we have the best technology and staff to ensure all the testing, sales, repair, and servicing needs. Our team has the skills, knowledge, and tools to comply with all the needs fluid bed granulation process.

Contact us right away to learn more about our high containment fluid bed granulator products and services and how they can benefit your pharmaceutical company.

CEO Message

Hey! This is Nikki. Thanks for visiting our website, and I hope we serve your needs meeting the international standards. We are pharmaceutical equipment and machine manufacturer with over 30 years of experience, and I would like to share with you our expertise in this field and answer any questions you may have about pharmaceutical machinery. I am always happy to help.