Cartoning Machine

- Cartoning Machine is an automatic equipment used to automatically pack products into cartons.

- Suitable for products of various shapes and sizes, such as medicines, food, etc.

- Improve production efficiency, reduce manual intervention, and ensure packaging consistency.

- Comply with industry regulations and standards, especially in the pharmaceutical field, which requires compliance with GMP and other specifications.

Cartoning Machine : Product Description

A cartoning machine is a specialized equipment used in various industries, including pharmaceuticals, food, and consumer goods, to automate the packaging process. It efficiently forms and seals cartons, also known as folding cartons or boxes, around products. The machine handles the tasks of product feeding, carton erection, filling, and carton sealing. It enhances packaging speed, accuracy, and consistency, streamlining production and ensuring efficient and reliable packaging for a wide range of products.

Paramenter Of Cartoning Machine

Cartoning machines come equipped with various features that enhance their functionality and efficiency. Here are some common features found in cartoning machines:

◈ Versatile Carton Handling: Cartoning machines are designed to handle different carton types, sizes, and styles. They can accommodate various carton materials such as cardboard, corrugated board, or plastic, allowing flexibility in packaging options.

◈ Automatic Operation: These automatic cartoning machines feature advanced automation systems that perform tasks such as carton erection, product feeding, insertion, and sealing. This reduces manual labor, increases production speed, and ensures consistent packaging quality.

◈ Adjustable Carton Dimensions: Automatic Cartoning machines offer flexibility in adjusting carton dimensions to suit different product sizes. They can be easily adjusted to accommodate a range of carton widths, lengths, and depths, allowing for versatility in packaging requirements.

◈ Product Detection and Orientation: Cartoning machines incorporate sensors and vision systems to detect and properly orient products before insertion into cartons. This ensures accurate and precise positioning of products within the cartons.

◈ Multiple Carton Closing Options: Depending on the specific machine, automatic cartoning machines may offer various closing options such as tuck-in flaps, hot melt glue, or adhesive tape. This allows for flexibility in choosing the most suitable carton closing method based on product requirements.

◈ Easy Changeover: Cartoning machines are designed for quick and tool-less changeover between different carton sizes or formats. This reduces downtime during production and allows for efficient switching between different packaging configurations.

◈ User-Friendly Interface: Cartoning machines often feature a user-friendly human-machine interface (HMI) that allows operators to monitor and control the machine’s functions easily. The interface may include touchscreens or control panels with intuitive navigation for convenient operation and adjustment.

◈ Safety Features: Safety is a critical aspect of cartoning machines. They are equipped with safety guards, emergency stop buttons, and interlocking mechanisms to ensure operator safety during machine operation.

◈ Integration with Other Equipment: Cartoning machines can be integrated into complete packaging lines, connecting with upstream and downstream equipment such as filling machines, labeling machines, and case sealers. This facilitates seamless production flow and automation.

◈ Quality Control and Rejection Systems: Advanced cartoning machines may include quality control features such as barcode scanners, vision systems, or weighing systems to ensure proper product presence, accuracy, and integrity. They can also incorporate rejection mechanisms to remove faulty or missing products from the packaging line.

These features contribute to the overall efficiency, reliability, and versatility of cartoning machines, making them essential equipment in various industries for automated and precise carton filling and sealing processes.

Cartoning machines have diverse applications across multiple industries. Some common applications of cartoning machines include:

◈ Pharmaceutical Industry: Cartoning machines are extensively used in the pharmaceutical sector for packaging various products such as blister packs, bottles, vials, ampoules, and tubes. They efficiently handle the cartoning of these items, ensuring accurate and secure packaging.

◈ Food Industry: Cartoning machines play a crucial role in packaging food products such as cereal boxes, frozen meals, confectionery items, snacks, and beverage cartons. These machines enable efficient and automated carton filling and carton sealing, maintaining product freshness and integrity.

◈ Cosmetics and Personal Care: Cartoning machines are used in the packaging of cosmetics, toiletries, and personal care products, including items like creams, lotions, soaps, perfumes, and cosmetic kits. They ensure efficient and attractive packaging for these products.

◈ Household and Consumer Goods: Various household and consumer goods, including cleaning products, batteries, hardware items, and electronic components, are packaged using cartoning machines. These machines streamline the packaging process, ensuring product protection and convenient handling.

◈ Automotive and Industrial: Cartoning machines are utilized in the automotive and industrial sectors for packaging spare parts, components, and small tools. They aid in efficient packaging, labeling, and organization of these items, ensuring easy identification and storage.

◈ E-commerce and Retail: Cartoning machines are employed in e-commerce and retail industries for packaging products ordered online or in-store. They automate the packaging process, facilitating quick and efficient fulfillment and ensuring secure shipping and display-ready packaging.

◈ Promotional and Display Packaging: Cartoning machines are used for creating promotional packs, gift sets, and display packaging. They enable the customization of cartons with attractive designs, logos, and branding, enhancing product visibility and appeal.

The working principle of an automatic cartoning machine can vary depending on the specific design and type of machine. However, the following steps provide a general overview of how cartoning machines typically operate:

◈ Carton Erection: The cartoning machine starts by picking flat carton blanks from a magazine or stack and moves them into position. The machine then folds and erects the cartons into their three-dimensional form.

◈ Product Feeding: The products to be packaged are fed into the cartoning machine either manually or automatically. This can involve conveyors, robotic arms, or other feeding mechanisms depending on the machine’s design.

◈ Carton Loading: The cartoning machine positions the opened cartons in a loading station where the products are inserted into the cartons. This can be done through mechanical pushers, pick-and-place mechanisms, or other methods.

◈ Leaflet Insertion (Optional): In some cases, cartoning machines have the capability to insert product leaflets or instructions into the cartons along with the products. This step ensures all necessary information is included in the final packaging.

◈ Carton Closure: Once the products are loaded into the cartons, the machine proceeds to close and seal the cartons. This can involve various methods such as tuck-in flaps, adhesive tape, or hot melt glue, depending on the machine’s configuration.

◈ Carton Discharge: The carton sealing and completed cartons are then discharged from the cartoning machine onto a conveyor or collection tray. They are ready for further processing, labeling, or packaging.

Throughout the process, cartoning machines may incorporate sensors, vision systems, and control systems to ensure the proper placement of products, detect errors or missing items, and maintain the quality of the packaging.

It’s important to note that there are different types of cartoning machines, such as horizontal cartoner and vertical cartoner, each with its own specific working principles. However, the general objective remains the same: to automate the process of erecting cartons, loading products, and sealing them efficiently and accurately.

More Details Of Cartoning Machine

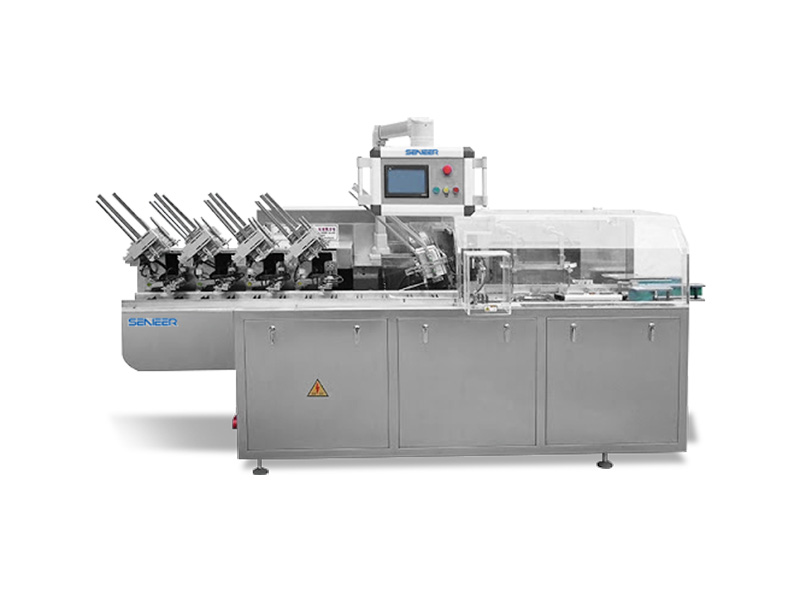

Model 1 Cartoning Machine

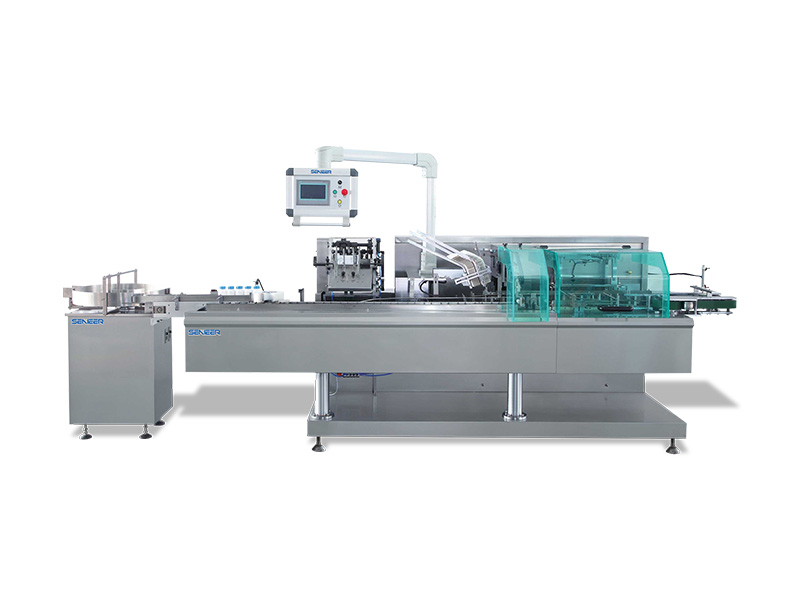

Model 2 Cartoning Machine

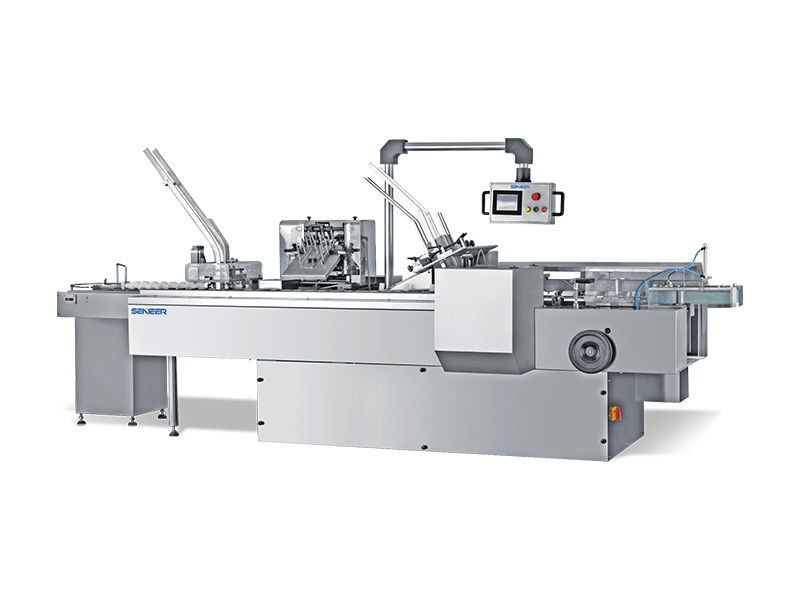

Model 3 Cartoning Machine

Any Question About Senieer Cartoning Machine

Why Global Company Trust Senieer

Top Quality Factory Price

We have a quality control department to verify each product at different phases, from the procurement of parts to finished products

As Your Layout, Customize Machine

According to your layout, we can suggest the best capacity and type for you, customize cartoning machine for you

Cartoning Machine Consult & Design Service

Save energy resource for you, professional engineers can improve the best processing solution. We have the experience to help add a tremendous amount of value to your project

ISO.CE Standard Qualified

We successfully obtaining the ISO9001:2008 certificate and CE security management system certificate, this is significant for Senieer in building enterprise image

Cartoning Machine Training & Maintance Service

Free cartoning machine training & maintenance service for you, we will provide your team in-depth training on safe operation and cartoning machine maintenance

Cartoning Machine Installation Service

Senieer offers cartoning machine installation & commissioning service for production products, your cartoning machine and control systems are qualified based on the GAMP life-cycle

Explore The Excellence Of Cartoning Machine, The Perfect Combination Of automation, Efficiency And Quality

Cartoning machines offer several advantages in packaging and automation processes. Here are some of the key advantages of using cartoning machines:

Increased Efficiency:

Cartoning machines automate the packaging process, significantly increasing the speed and efficiency of packaging operations. They can handle high volumes of products and consistently maintain a fast packaging rate, leading to improved overall productivity.

Time And Labor Savings:

By automating the cartoning process, companies can save time and reduce labor costs. The machines can perform tasks such as erecting cartons, inserting products, and carton sealing, eliminating the need for manual labor and reducing the chances of errors.

Improved Product Protection:

Automatic Cartoning machine ensure that products are securely and properly packaged, reducing the risk of damage during transportation and storage. They can handle delicate and fragile items with precision, providing reliable protection and minimizing product waste or returns.

Versatility and Flexibility:

Automatic Cartoning machines are designed to handle various carton styles, sizes, and product configurations. They can accommodate different types of products, such as bottles, tubes, blister packs, pouches, and more, offering versatility in packaging options. Moreover, they can be easily adjusted and reconfigured to accommodate different packaging requirements, allowing for flexibility in production.

Enhanced Accuracy and Consistency:

Manual packaging processes can be prone to errors, such as misalignments, incorrect product counts, or inconsistent folding and carton sealing. Cartoning machines provide accurate and consistent packaging results, ensuring that each carton is correctly filled, sealed, and labeled, which improves product quality and customer satisfaction.

Traceability and Serialization:

Many cartoning machines are equipped with advanced features like barcode readers and serial number printing capabilities. This enables the tracking and tracing of products throughout the supply chain, enhancing product safety, quality control, and regulatory compliance.

Increased Speed To Market:

With faster and more efficient packaging processes, cartoning machines contribute to reducing the time it takes to bring products to market. This can give companies a competitive edge by enabling them to meet customer demands quickly and respond to market trends promptly.

Cost Savings:

While cartoning machines require an initial investment, they can lead to long-term cost savings. By streamlining packaging operations, reducing labor costs, minimizing product waste, and optimizing production efficiency, companies can achieve higher profitability and a faster return on investment.

Overall, horizontal cartoning machines and vertical cartoning machines offer numerous advantages, including improved efficiency, time and labor savings, enhanced product protection, versatility, accuracy, traceability, and cost savings. These benefits make them a valuable asset for companies in various industries involved in packaging and manufacturing processes.

Discover the power of automation and efficiency with Senieer’s advanced cartoning machines. Revolutionize your packaging process and unlock a world of benefits. Increase productivity, save time and labor costs, and ensure precise and consistent packaging results. Our versatile machines accommodate various carton styles and product configurations, guaranteeing superior protection for your valuable products. Experience enhanced traceability, improved product quality, and faster speed to market. With Senieer horizontal cartoning machines and vertical cartoning machines, you’ll gain a competitive edge and maximize your profitability. Don’t miss out on this opportunity to elevate your packaging operations. Contact us today and take the first step toward a more efficient and successful future.