Hammer Mill: Principle, Configuration and Application

Hammer mill, or hammer mill crusher, is a grinding machine used to grind and pulverize bulk materials or solid granules into required sizes. The grinding materials is wide, including bulks, big granules, mixtures of powder, etc. It has a wide application areas such as pharmaceutical, chemical, food, medicine, agricultural and recycling industries due to its excellent design and structure. Next, we will discuss the working principle, configuration and application of hammer mill.

Working Principle of Hammer Mill

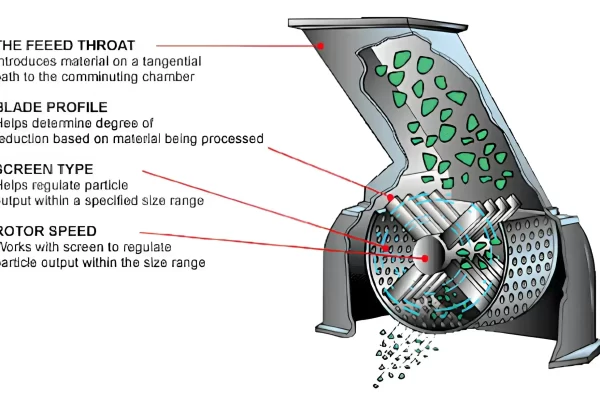

The working process of hammer mill machine is simple and intuitive. Its working principle is based on the impact force mechanism. Materials enter the crushing chamber through the feeding hopper, and then are ground and crushed by the high-speed rotating crushing blades or hammers into the needed material sizes. There are three key factors affecting the particle size of hammer mills: configuration of hammers or crushing blades, rotating speed of shafts and screen mesh size. After multiple crushing of materials in the crushing chamber, only the particles meeting the screen mesh size can pass through the screen mesh.

Configuration of Hammer Mill

There are various types of hammer mills in the industries and each of them has a big or slight differences in the configuration. So in this article, only taking pharmaceutical hammer mill as an example to demonstrate its basic configuration. The key components of a pharmaceutical hammer mill include feeding hopper, rotor, hammers, screen mesh, crushing chamber and control system.

Feeding hopper

The materials ready to be ground enter through this feeding hopper. Although the structure of feeding hopper is simple. There are also many details needing to notice and take care. Its design must ensures the consistent and uniformly flowing of materials, avoiding blocking, and the construction material of feeding hopper must be compatible with the grinding materials to ensure there is no chemical interaction between them.

Rotor

Located in the center of machine, rotates usually at the speed of 2500~6000 rpm. The key component consists of a central shaft with hammers attached to it, reducing the size of pharmaceutical granules through high-speed grinding.

Hammers

In the pharmaceutical area, the material of hammers is stainless steel 316L, and the shapes are usually stirrup-shaped or strip-shaped. Each rotor attaches 4~8 hammers. The speed range of hammers is 0~6000 rpm.

Screen mesh

It is located between the chamber and the rotors. It plays an importance role in controlling the final particle size. By using the changeable screen mesh, can precisely customize the particle size distribution. When the speed of rotors is stable, the relatively thick screen mesh can produce more softer particles.

Crushing chamber

Materials are crushed and ground multiple times in this section, and only the required particle sizes can pass through the screen mesh.

There is an experiment shows that the best screen mesh size is 3mm and if increases the throughput of hammer mill from 9.6 to 16 t/h, the energy efficiency can enhance by 18%. it shows that there are many details need to consider in the design and manufacture process if you want to maximize the performance of your hammer mills.

Features of Hammer Mill

Crushing screen

The screen is a plate-type mesh, and the material can be customized to SUS304/316L or alloy steel blades as per the client’s requirements. The mesh sizes range from 40 mesh, 60 mesh, 80 mesh, 100 mesh, 120 mesh, 140 mesh, 150 mesh, 200 mesh, and 250 mesh. The screen is welded to the frame in a butt-welding style and is positioned at the top inside.

Air seal

A compressed air sealing device is installed at the bearing box connection on the rear end cover of the barrel. The air seal consists of a stainless steel ring with an annular groove and two PTFE lip seals on each side. The annular groove in the stainless steel ring is connected to the compressed air pipe. When compressed air is blown into the stainless steel ring, the airflow flows along both sides, with one end blowing into the barrel and the other end flowing out along the bearing baffle through the exhaust hole. This effectively prevents materials inside the barrel from entering the bearing during rotation due to the gap between the shaft and sleeve, thus avoiding jamming. It also serves a self-lubricating and heat dissipation function.

Safety Protection

An electric limit switch is installed above the connection between the movable door and the barrel flange. If the movable door is not securely closed, the equipment will not operate. This helps prevent accidental safety incidents.

Application of Hammer Mill

The application of hammer mill is wide due to its simplicity and powerful functionality. Hammer mills are widely applied in the industries of pharmaceutical, food, chemical, medicine and agricultural fields.

Pharmaceutical: used to grind bulk materials and solid granules, controlling uniform distribution of APIs in the tablets and capsules to ensure the accuracy of dosage.

Food processing: used to grind various food ingredients like grains, spices, etc., to produce uniform particles which is important to the texture and flavour of final products.

Agricultural: used to process materials like grains and feeds into animal feed.

Chemical: used to reduce the sizes of raw materials and intermediate, which is significant for optimizing the chemical interaction and formula. The uniform particle size enhances the solubility and reactivity of chemicals.

Mining: used to crush the rocks and ores for mineral extraction.

Hammer mill is usually used in conjunction with dust-free feeding station, vacuum conveying system, cyclone screening machine, powder filling machine, powder packing machine, etc., to form a complete powder filling line.

Choose Your Interested Production Line

Bottle Filling Line

Granulation Line

Blister Packaging Line

Powder Filling Line